An open source, embedded, high performance g-code-parser and CNC milling controller written in optimized C that will run on an Arduino Mega2560 - gnea/grbl-Mega. No G code simulator is designed to actually produce the code itself, for this you need to write your own basic programs or use Cad Cam software to produce complex parts. Fusion 360 Cad Cam software is free for hobbyist cnc machinists and can produce tool paths for anything you want as long as you have a Cad model. ANILAM G Code List for CNC Mill Controls like 6000M G-codes initiate motion commands, canned cycles and various machine and CNC functions. More than one G-code may be specified per CNC Fanuc G33 G32 Threading G Code.

- Cnc G Code List Download Pdf

- Cnc G Code List Download

- Cnc G Code List Download Free

- Cnc G Code And M Code List Pdf Download

- Cnc G Code List Download Full

G-codes are also called preparatory codes (preparatory functions).

Contents

- Complete G Code List

- G32 Thread cutting

- G74 End face peck drilling

- G76 Multiple threading cycle

- G92 Thread cutting cycle

Complete G Code List

List of G-codes commonly found on Fanuc and similarly designed CNC controls

| G Code | Group | Function | ||

| A | B | C | ||

| G00 | G00 | G00 | 01 | Positioning (Rapid traverse) |

| G01 | G01 | G01 | Linear interpolation (Cutting feed) | |

| G02 | G02 | G02 | Circular interpolation CW or helical interpolation CW | |

| G03 | G03 | G03 | Circular interpolation CCW or helical interpolation CCW | |

| G04 | G04 | G04 | 00 | Dwell |

| G07.1(G107) | G07.1(G107) | G07.1(G107) | Cylindrical interpolation | |

| G08 | G08 | G08 | Advanced preview control | |

| G10 | G10 | G10 | Programmable data input | |

| G11 | G11 | G11 | Programmable data input cancel | |

| G12.1(G112) | G12.1(G112) | G12.1(G112) | 21 | Polar coordinate interpolation mode |

| G13.1(G113) | G13.1(G113) | G13.1(G113) | Polar coordinate interpolation cancel mode | |

| G17 | G17 | G17 | 16 | X Y plane selection |

| G18 | G18 | G18 | Z X plane selection | |

| G19 | G19 | G19 | Y Z plane selection | |

| G20 | G20 | G70 | 06 | Input in inch |

| G21 | G21 | G71 | Input in mm | |

| G22 | G22 | G22 | 09 | Stored stroke check function on |

| G23 | G23 | G23 | Stored stroke check function off | |

| G25 | G25 | G25 | 08 | Spindle speed fluctuation detection off |

| G26 | G26 | G26 | Spindle speed fluctuation detection on | |

| G27 | G27 | G27 | 00 | Reference position return check |

| G28 | G28 | G28 | Return to reference position | |

| G30 | G30 | G30 | 2nd, 3rd and 4th reference position return | |

| G31 | G31 | G31 | Skip function | |

| G32 | G33 | G33 | 01 | Thread cutting |

| G34 | G34 | G34 | Variable—lead thread cutting | |

| G36 | G36 | G36 | 00 | Automatic tool compensation X |

| G37 | G37 | G37 | Automatic tool compensation Z | |

| G40 | G40 | G40 | 07 | Tool nose radius compensation cancel |

| G41 | G41 | G41 | Tool nose radius compensation left | |

| G42 | G42 | G42 | Tool nose radius compensation right | |

| G50 | G92 | G92 | 00 | Coordinate system setting or max. spindle speed setting |

| G50.3 | G92.1 | G92.1 | Workpiece coordinate system preset | |

| G50.2(G250) | G50.2(G250) | G50.2(G250) | 20 | Polygonal turning cancel |

| G51.2(G251) | G51.2(G251) | G51.2(G251) | Polygonal turning | |

| G52 | G52 | G52 | 00 | Local coordinate system setting |

| G53 | G53 | G53 | Machine coordinate system setting | |

| G54 | G54 | G54 | 14 | Workpiece coordinate system 1 selection |

| G55 | G55 | G55 | Workpiece coordinate system 2 selection | |

| G56 | G56 | G56 | Workpiece coordinate system 3 selection | |

| G57 | G57 | G57 | Workpiece coordinate system 4 selection | |

| G58 | G58 | G58 | Workpiece coordinate system 5 selection | |

| G59 | G59 | G59 | Workpiece coordinate system 6 selection | |

| G65 | G65 | G65 | 00 | Macro calling |

| G66 | G66 | G66 | 12 | Macro modal call |

| G67 | G67 | G67 | Macro modal call cancel | |

| G68 | G68 | G68 | 04 | Mirror image for double turrets ON |

| G69 | G69 | G69 | Mirror image for double turrets OFF | |

| G70 | G70 | G72 | 00 | Finishing cycle |

| G71 | G71 | G73 | Stock removal in turning | |

| G72 | G72 | G74 | Stock removal in facing | |

| G73 | G73 | G75 | Pattern repeating | |

| G74 | G74 | G76 | End face peck drilling | |

| G75 | G75 | G77 | Outer diameter/internal diameter drilling | |

| G76 | G76 | G78 | Multiple threading cycle | |

| G80 | G80 | G80 | 10 | Canned cycle for drilling cancel |

| G83 | G83 | G83 | Cycle for face drilling | |

| G84 | G84 | G84 | Cycle for face tapping | |

| G86 | G86 | G86 | Cycle for face boring | |

| G87 | G87 | G87 | Cycle for side drilling | |

| G88 | G88 | G88 | Cycle for side tapping | |

| G89 | G89 | G89 | Cycle for side boring | |

| G90 | G77 | G20 | 01 | Outer diameter/internal diameter cutting cycle |

| G92 | G78 | G21 | Thread cutting cycle | |

| G94 | G79 | G24 | Endface turning cycle | |

| G96 | G96 | G96 | 02 | Constant surface speed control |

| G97 | G97 | G97 | Constant surface speed control cancel | |

| G98 | G94 | G94 | 05 | Per minute feed |

| G99 | G95 | G95 | Per revolution feed | |

| – | G90 | G90 | 03 | Absolute programming |

| – | G91 | G91 | Incremental programming | |

| – | G98 | G98 | 11 | Return to initial level |

| – | G99 | G99 | Return to R point level | |

G00 Positioning (Rapid traverse)

G01 Linear interpolation (Cutting feed)

G02 Circular interpolation CW or helical interpolation CW

G03 Circular interpolation CCW or helical interpolation CCW

G04 Dwell

G10 Programmable data input

G20 Input in inch

G21 Input in mm

G32 Thread cutting

G32 Taper Threading

G33 Thread Cutting

G70 Finishing cycle

G71 Stock removal in turning

G72 Stock removal in facing

G73 Pattern repeating

G74 End face peck drilling

Peck drilling in Z axis.

G74 Peck Drilling Cycle

G74 Face Grooving

G75 Outer diameter/internal diameter drilling

Grooving in X axis.

G76 Multiple threading cycle

Thread cutting cycle, G76 threading cycle, Fanuc G76 threading cycle, G76 thread cycle.

G76 Threading Cycle One Line Format

G76 Taper Threading

G76 Multi Start Threading

G76 Thread Infeed

G92 Thread cutting cycle

CNC Fanuc G92 Threading Cycle, G92 thread cutting cycle.

G92 Taper Threading Cycle

G94 Facing Cycle (Endface turning cycle)

G94 Feed Per Minute / G98 Feed Per Minute

G95 Feed Per Revolution / G99 Feed Per Revolution

Do you want to be a better CNC’er in 37 Seconds? Get Better Tool Life, Surface Finish, and Material Removal Rates Fast. It’s that easy. You can install and get results now. |

Quick: What’s the Best Free CAD Software out there? How about the Best Free CAM Software?

We can help! Here’s your guide to the best free CNC software that’s out there. Some of it is ours, some is from 3rd parties.

Is “Free” The Right Choice?

This may seem an odd way to get started, but I need to ask the question in all seriousness. You may have heard the expression, “There ain’t no such thing as a free lunch.”

Sometimes free is totally awesome and there are no strings attached. Other times free makes us choose vastly inferior solutions. We spend so much time fighting with the free software that in the end, had we spent just a little bit, we might have come out a lot better. And sometimes free has sneaky hidden costs.

Keep all that in mind as you check out our choices for the best Free CNC Software you can find.

CNCCookbook Free CNC Software

We always provide a free trial for our software. In addition, when we’re introducing new products, we release them for free while in Beta test and don’t charge until we finish the software. Typically you use it for many months if not a year or two when that happens. We don’t believe in shipping software until it is great. In addition to all that, some of our software is filled with a ton of free features even if you never subscribe.

So checkout our free stuff!

G-Wizard Calculator

Cnc G Code List Download Pdf

We do a terrible job advertising it, but most of G-Wizard Calculator is free. Seriously. You sign up for the free trial, and when that ends, even if you don’t purchase, most of the tabs will go right on working for you. There’s a giant treasure trove of useful calculators, utilities, and reference information there including:

- Fancy scientific calculator with automatic unit conversions and much more.

- The ultimate productivity hack for busy people–the same ToDo list with Pomodoro timer system I use myself to get all this crazy stuff done for CNCCookbook.

- Geometry and Trig Calculators for Right Triangles, Oblique Triangles, Bolt Circles, Dovetails, Tapers, Chamfers, Drilling, Chords, True Position, Points, Turner’s Cubes

- Fits and Tolerances for ISO 286, ANSI B4.2, and DIN 7172

- Thread Database with all the dimensions, tapping drills, and more

- Drill Chart

- Fastener Database with dimensions for Socket Head and Flat Head Cap Screws

- Weights and Volumes for standard metal structural shapes as well as standard lumber sizes

- Thermal Expansi0n Calculator

- Electrical Ohms Law Calculator

- Resistor Color Codes

- CNC Servo and Stepper Motor Sizing Calculators

- G- and M-Code Quick Reference

- Hardness Quick Reference with Rockwell (A, B, C, D, 15H, 30H, 45N), Brinell (Std, Hultgren, Tungsten), Vickers, and Shore scales

- Rigidity Calculator to help figure your tool rigidity

- Chatter Calculator to figure the right spindle speed to stop chatter

- Geometric, Dimensioning, and Tolerancing Quick Reference

Phew! I can hardly keep up with all of it myself. I know there a lifetime subscribers who are still delighted at the new things they discover. And we just keep adding more all the time!

I thought I’d make a quick video showing how it all works:

All of this will save you time digging through machinery’s handbook or trying to Google for it. It’s all stuff that I use constantly and you will love having it at your fingertips. So what are you waiting for–give the G-Wizard free Trial a try:

[ I Savvy, Get Me My Free Trial Now! ]

BTW, you have the choice of buying the software outright (lifetime subscription) or subscribing. Now I hear all the time from hobbyists who don’t think they can afford G-Wizard. First thing is that one year is cheap–not much more than a single cutter costs. But okay, let’s suppose you still think that’s too expensive. The thing is, at the end of that 1 year,Feeds and Speeds keep right on working too.

What’s the catch?

The catch is that once the subscription expires, there’s a spindle power limit equal to 1 horsepower for each year you subscribe. This is perfect for a hobbyist. A small CNC Router may not be able to use more than a 1 horsepower cut–tiny machines just aren’t rigid enough. That means a lifetime of Feeds and Speeds, limited to 1 HP, for just the cost of 1 year of subscription. It’s perfect for the hobbyist trying to save.

Cnc G Code List Download

And, if you ever get a more powerful machine, just re-subscribe to unlock the limit. No muss, no fuss.

Here you can create the content that will be used within the module.

G-Wizard Editor

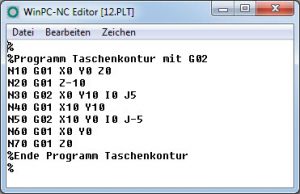

Everybody who tries G-Wizard Editor loves it because it’s the first G-Code software whose focus is on simplifying g-code, and it’s also the first to build in Conversational CNC. With conversational CNC, you can work without using CAD. Just answer a few simple questions and GW Editor will write the g-code for you. It’s for all those jobs you were thinking would be faster on a manual machine, and it’s a totally free additional module you get with G-Wizard Editor.

Free DXF Files

[ Get my Free DXF Files Now! ]

Download our free DXF files and be cutting cool patterns on your CNC Laser, Router, Waterjet, or other machine before you know it.

More Free CNC Software

Best Free CAD Software

Which one of these packages is your pick for the Best Free CAD Software out there?

| A9 CAD | CAD | http://www.a9tech.com/products/a9cad/ |

| Blender | CAD | https://www.blender.org/ |

| Draftsight | CAD | https://www.solidworks.com/product/draftsight |

| eCabinet: CAD for custom cabinet makers | CAD | http://www.ecabinetsystems.com/ |

| gCAD3d | CAD | http://www.cadcam.co.at/freiter/gCAD3D_en.htm |

| FreeCAD | CAD | https://www.freecadweb.org/ |

| Google Sketchup | CAD | https://sketchup.google.com/ |

| Fusion 360 | CAD + CAM | https://www.autodesk.com/products/fusion-360/students-teachers-educators |

| GraphiteOne CAD | CAD | https://www.graphiteone-cad.com/ |

| HeeksCAD | CAD | https://github.com/Heeks/heekscad |

| Minos | CAD | http://www.le-boite.com/minos.htm |

| nanoCAD | CAD | https://nanocad.com/ |

| OnShape | CAD | https://www.onshape.com/ |

| Solid Edge Free 2D Drafting | CAD | http://www.solidedge.com/free2d/ |

| TinkerCAD | CAD | https://www.tinkercad.com/ |

| Wings 3D | CAD | https://www.wings3d.com/ |

Free CNC CAM Software

| Estlcam | CAM | http://www.estlcam.com/ |

| Free Mill: 3D Milling from the makers of Visual Mill | CAM | http://www.mecsoft.com/freemill.shtml |

| DeskProto | CAM | https://www.deskproto.com/products/free-ed.php |

| HSMExpress | CAM | http://www.hsmworks.com/hsmxpress/ |

| Fusion 360 | CAD + CAM | https://www.autodesk.com/products/fusion-360/students-teachers-educators |

| G-Simple | CAM | https://www.gsimple.eu/ |

| Heeks CAD/CAM | CAM | https://www.heeks.net/ |

Other Free CNC Software

| GCode Ripper | Wrap GCode for 4th Axis or do Engraving on Irregular Surfaces after Probing | See article link |

| LinuxCNC / EMC2 | Free CNC Control Software | https://www.linuxcnc.org/ |

| Jedicut | CNC Foam Cutting | http://www.aeropassion.net/index-en.php |

| Ace Converter | DXF to G-Code | http://www.dakeng.com/ace.html |

| 2linc Engraving Software: Light Version | Engraving Software | http://www.2linc.com/cnc_programming_software.htm |

| DeskEngrave | Engraving Software | http://www.deskam.com/download.html |

| PCB-GCODE | G-Code for Eagle PCB | https://groups.yahoo.com/group/pcb-gcode/ |

| Auto-trace | Image or bitmap to g-code | http://autotrace.sourceforge.net/ |

| Image to G-Code | Image or bitmap to g-code | http://www.imagetogcode.com/ |

| Scan2CNC | Image or bitmap to g-code | http://www.gravomaster.com/Tristan_Dean/scan2cnc.html |

| MaxCut | Nesting | http://www.maxcut.co.za/ |

Free CNC Software FAQ

Cnc G Code List Download Free

What is CNC Software?

CNC Software is the Digital Tooling used to create programs for CNC Machines. There are many kinds, but CAD and CAM are the most common.

What is the minimum CNC Software for a Beginner?

A beginning CNC’er needs to learn to use CAD Software for creating designs, CAM Software to convert the designs to g-code, and Feeds and Speeds Software to determine the proper cutting feeds and speeds for their CAM software to use.

What is the most popular CAD Software for CNC?

Cnc G Code And M Code List Pdf Download

Fusion 360 followed by Solidworks are the most popular CAD Software packages among CNC’ers according to CNCCookbook’s CAD Survey. Fusion 360 is free for non-business users and some small business users.

What is the most popular CAM Software?

Fusion 360 is the most popular CAM Software followed by Vectric/Aspire and Mastercam according to CNCCookbook’s CAM Survey. Fusion 360 is free for non-business users and some small business users.

Categories

- 3D Printing (61)

- Blog (904)

- CNC Basics (270)

- CNC Manufacturing & Job Shops (214)

- CNC Products (255)

- CNC Projects (201)

- CNC Router (68)

- Cool (249)

- DIY CNC (83)

- Feeds and Speeds (137)

- GCode (80)

- Guest-Post (19)

- LiveStreams (4)

- Machining Techniques (445)

- Manual Machining (43)

- NewFeatures (18)

- Quoting and Estimating (14)

- Software (257)

Cnc G Code List Download Full

GCode is Complicated

G-Wizard Makes it Easy